Quick tips for hydraulic hose maintenance

Hydraulic hoses are an essential component of any hydraulic system. If a hose fails, this can have a knock-on effect on other components and ultimately lead to serious damage, downtime and costly repairs.

Hoses and fittings can crack and burst over time but for the most part, this can be avoided by ensuring that preventative maintenance is in place.

Keeping your hydraulic hoses in check is a fairly simple task, but one that requires regular commitment if you want to keep your system running optimally and avoid unnecessary repair or replacement costs.

Here are a few key hydraulic hose maintenance tips that will help to ensure the reliability of your equipment.

1. Put a maintenance routine in place

First and foremost, establish a regular routine. Hydraulic hose maintenance shouldn’t be performed on an ad hoc basis or left until something goes wrong. Hoses should be inspected on a regular basis, in order to identify any possible issues and rectify them immediately.

Introducing a maintenance routine can take some adjusting at first, but it should be conducted at least once a month thereafter. Businesses that stick to this will typically find that their equipment lasts longer, which ultimately prevents downtime and saves them money in the long run.

Below are some of the key things that should be ticked off your maintenance checklist each month.

2. Conduct regular visual inspections

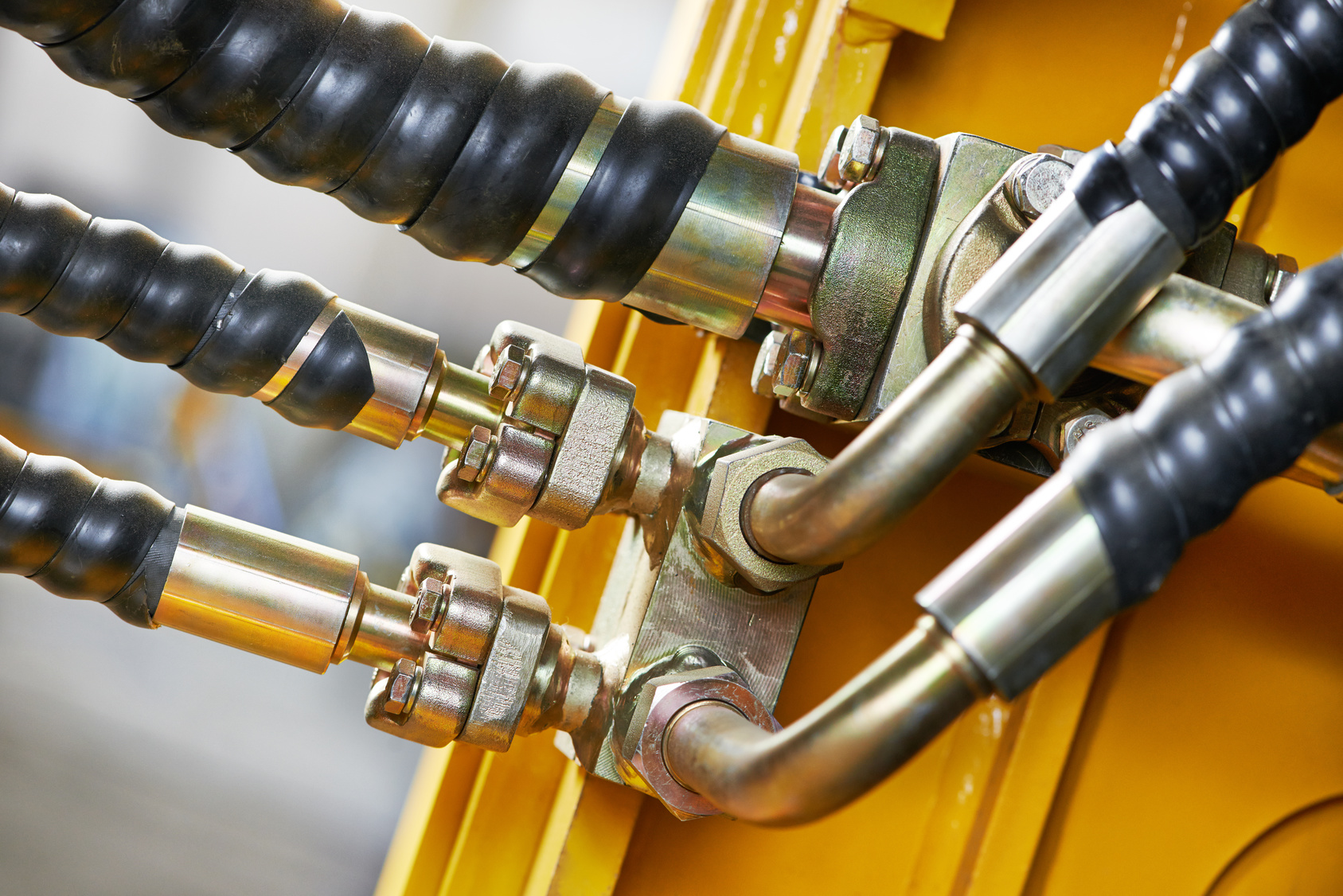

Visual inspections can be a powerful tool in identifying any possible issues before they come to light. Keep a close eye on your hoses and look for any cracks, abrasions, bends or twisting – these can all be telltale signs that your hose needs repairing or replacing.

Ensure that your team are all up to speed with what to look out for, and leave no stone unturned. A damaged hose can lead to external leaks which can result in underperformance and pose a great deal of health and safety risks.

3. Maintain the correct hydraulic fluid temperature

Every hydraulic hose has a temperature rating, and these are specified for good reason. These ratings will vary between hoses, and they dictate the temperature range that the fluid should be within.

Make your team aware of the temperature rating of your specific hose, and ensure that the fluid doesn’t exceed the maximum temperature. If it does, then the hose risks cracking and can lose its flexibility.

4. Don’t exceed pressure ratings

Similarly, hydraulic hoses have pressure ratings which should not be exceeded. Pressure ratings are in place to protect the hose and the safety of your operators, so it’s an important measurement to keep an eye on.

Using higher pressures within the hydraulic system than specified can be potentially dangerous due to the risk of bursting. Not only can this lead to system downtime, but it also poses huge health and safety risks.

5. Be aware of leaks

Hydraulic leaks should never be ignored, no matter how minor they may first appear. If you suspect a leak within your system, whether internal or external, it’s a sign that something isn’t quite right.

Hydraulic leaks can be incredibly dangerous and reduce the operating efficiency of your system. A leak could be caused due to a rupture or crack in the hose, or a loose hose fitting. Either way, be sure to power down the system to inspect the hose and its fittings, and resolve any issues immediately.

6. Prevent contamination

It’s important to ensure that your hydraulic fluid is free from contamination for many reasons, including the safety of the hose. If the fluid travelling through the hose carries debris this can cause significant damage to the inner tube and therefore lead to further complications.

This is where your hydraulic filters come into play. Regularly check to ensure that your filters are functioning properly and effectively removing any debris from the fluid.

Hydraulic filters should also be changed frequently, depending on how long they have been operating. Check your manufacturer guidelines and keep a note of when they need to be replaced.

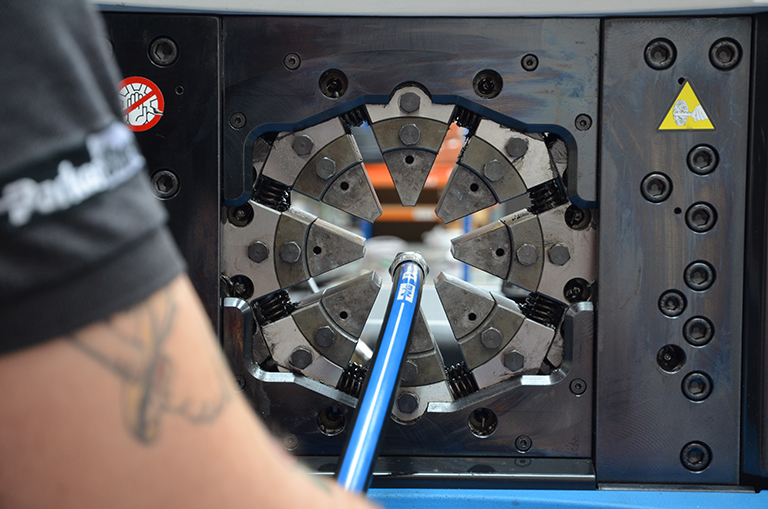

7. Replace any defect hoses immediately

It goes without saying that if you notice any signs of damage or wear on your hydraulic hoses, they should be replaced immediately.

When conducting regular maintenance checks, you should be able to spot any telltale signs that your hose isn’t in optimal condition. These signs shouldn’t be ignored, and to avoid further damage to your system or other components, the issue should be rectified as soon as possible.

To summarise, if you take good care of your hydraulic hoses, they should last you for many years to come. By implementing these maintenance tips, you’ll help to elongate their lifespan and ultimately keep your system in top working condition.

If you’re looking for a reputable company to repair or replace your hydraulic hose, get in touch with us. We offer hydraulic hose servicing and repairs, and custom-built assemblies designed to your exact specifications.