Should you replace or repair hydraulic pumps?

Hydraulic pumps, whilst built to be robust and withstand harsh conditions, are prone to wear and tear over time.

Unsurprisingly this is more prevalent in a pump than any other component, since the hydraulic pump needs to run at all times. Couple this with the fact that they are crucial components of any hydraulic system, and a fault or failure at the pump can be extremely detrimental to operations.

If you’ve found yourself in this situation then you may be left wondering ‘can my pump be repaired or does it need replacing?’

The good news is that hydraulic pumps can absolutely be repaired. However, this depends on the component’s current state, and whether a repair or replacement is the most feasible option.

This blog aims to give you some insight into understanding when your hydraulic pump needs some attention and whether it’s time for a repair or replacement.

Common hydraulic pump issues

Understanding the telltale signs that your hydraulic pump may need to be inspected is the first step in taking action and preventing an equipment failure. Keep an eye out for the following symptoms:

Unusually loud noises

When you hear any unexpected sounds coming from your hydraulic pump, that’s a dead giveaway sign that something isn’t quite right.

To be clear, the sheer speed and pressure of hydraulic fluid passing through the pump can generate a certain level of noise, but you should be able to tell the difference between normal operating sounds and abnormally loud commotion.

This can be caused by anything from worn seals to the presence of air in the system leading to cavitation. In this case, the pump needs to be inspected straight away to diagnose the specific issue.

Leaks

Hydraulic pumps may experience internal or external leaks, which can lead to a series of other issues.

A leak can decrease the pressure and therefore performance of the pump, so if you notice a sudden pressure drop then it should be relatively obvious that this needs to be checked.

If a loose valve is the culprit of the leak, then this can be rectified relatively quickly. However, if the pump itself appears to be damaged then this should be examined to see if it can be repaired or needs a replacement.

High temperatures

As a general rule, the temperature in a hydraulic system should never reach beyond 82°C. Anything above this could indicate that the system isn’t cooling down effectively, and high temperature changes can lead to serious pump damage.

If you notice a sudden temperature spike in your system, it’s recommended that you get it checked as soon as possible.

Hydraulic pump repair, rebuild & replacement

When you’re stuck with an underperforming pump, there are essentially three routes you can go down: repair, rebuild or replacement.

To clear up any confusion around the three options, we’ll summarise each below:

Hydraulic pump repair

When repairing a hydraulic pump, the component is assessed to identify the individual parts that have failed. As such, these individual parts can possibly be fixed to get it back up and running.

Hydraulic pump rebuild

A rebuild differs from a repair in that the pump is entirely disassembled, with each part individually inspected for signs of damage or wear. Any part that isn’t up to scratch may possibly be reconditioned or replaced as needed. Then, the entire pump will be reassembled and tested to ensure optimal performance.

Hydraulic pump replacement

This is a fairly obvious one, but a replacement requires removing the old pump and replacing it with a brand new one. For a successful replacement, you’ll need to know as much information as possible about the pump (model number, manufacturer, attributes etc) in order to find a direct or compatible replacement.

So, which option should you choose?

When it comes to rescuing a faulty hydraulic pump, time is of the essence. Typically, you’ll want a quick fix solution here and now. Naturally, that’s why many people opt for a repair or rebuild over a replacement.

The turnaround time for repairs and rebuilds is often much shorter than the time it takes to source, manufacture and deliver a compatible replacement pump. Longer delays mean prolonged downtime, and that’s something that any business wants to avoid.

Of your hydraulic pump has been operating for many years with no issues until today – it’s likely that it may have simply come to the end of its life and therefore you’ll require a replacement.

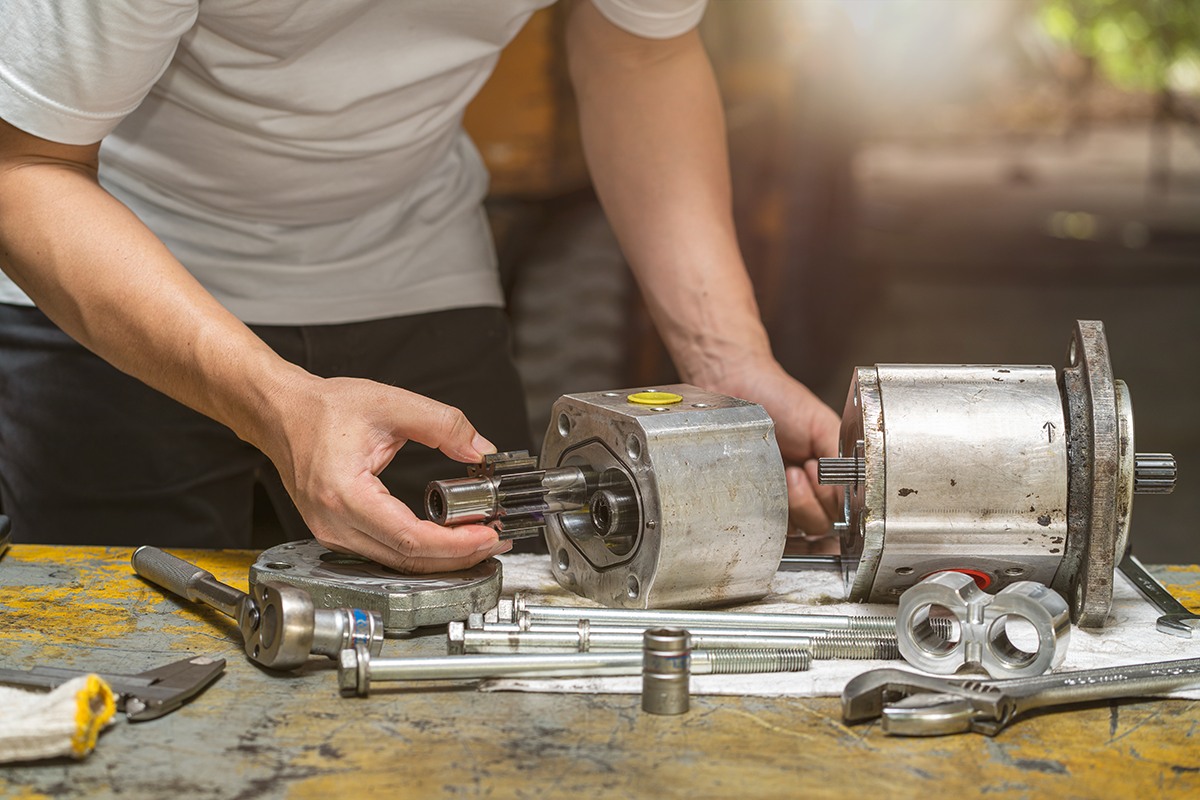

Let the experts decide

Repairing, or even replacing, hydraulic equipment requires a high level of specialised skill to correctly diagnose the fault and deliver the most suitable solution. If you try to take this challenge on yourself with limited knowledge, you may just end up paying the price.

It’s essential to get repairs right the first time around, to avoid costly issues in the future. Expert hydraulic engineers will be able to put the correct diagnosis and have procedures in place to ensure that your hydraulic pump is to standard.

Derek Lane & Co are a team of expert engineers and technicians, specialising in the repair and overhaul of hydraulic equipment. We aim to provide an end-to-end service that keeps your equipment running at peak performance with minimal downtime for your business.

Our 20,000sq. Ft. Engineering facilities are based in Newton Abbot, Devon and is fully equipped with the tools and equipment needed to carry out repairs and rebuilds on most hydraulic pumps. We work with only quality-approved suppliers, so you can be assured that your equipment is returned to you in top working condition.

If you’re looking for a reliable hydraulic pump repair specialist in the UK, get in touch with Derek Lane & Co today.