The key elements of a hydraulic hose assembly explained

Hydraulic hose assemblies are used in many applications and are an integral part of just about any hydraulic system.

Far from a minor component, hydraulic systems rely on the hose to handle liquid pressure and flow – allowing hydraulic fluid to be transferred between components at a controlled pressure and temperature.

Composed of the hose and hose end fittings, the hose assembly is essentially the driving force behind the mechanics of the entire hydraulics operation – without it, the system wouldn’t be able to run.

So, now you know how important hydraulic hose assemblies are, let’s take a look at how they are constructed, and the difference between hose types.

The key components of a hydraulic hose assembly

Hydraulic hoses come in many different shapes, sizes and materials. However, one thing that remains the same across the board is the main components that make up a hose assembly. These are:

Inner lining

The internal part of the hose is typically a plastic or rubber inner lining which houses the hydraulic fluid. The material chosen will depend on the type of fluid that it will contain, in order to guarantee compatibility and avoid corrosion.

Reinforcement

The inner lining is encased in a coiled or braided wire reinforcement layer to provide support and enable the hose to withstand both internal and external pressure.

Outer layer

The third layer of a hydraulic hose is a protective cover that protects the hose against damage from external sources such as the environment, wear and abrasion. The outer layer is made from a rigid yet flexible material which ensures the integrity of the fluid is contained without impacting the operations.

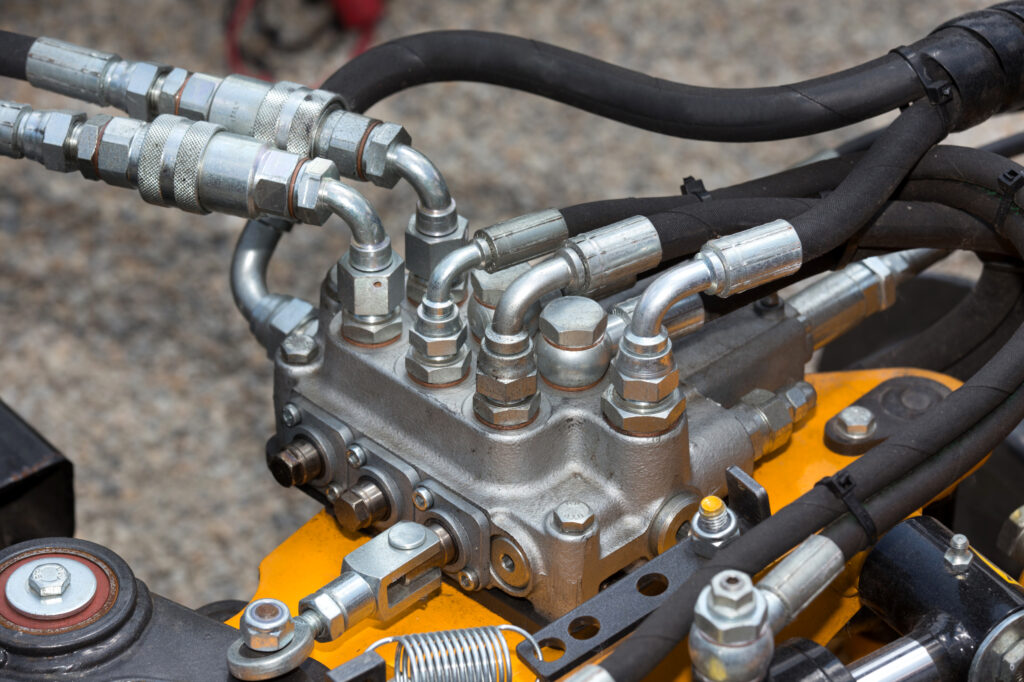

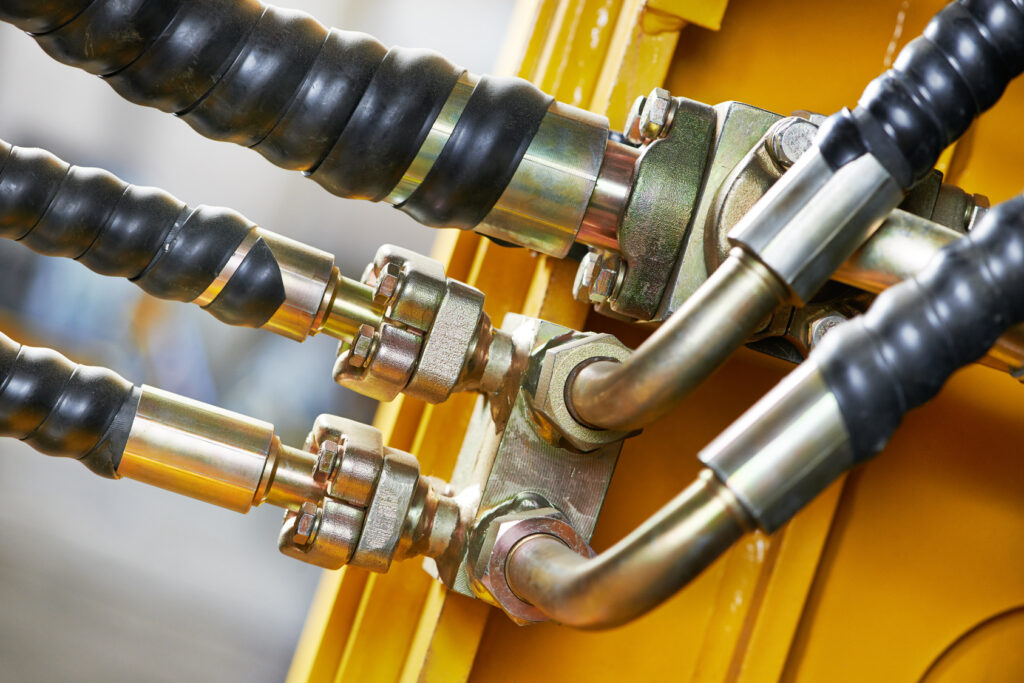

Hose end fittings

A crucial part of any hydraulic hose assembly. Hose end fittings are essential for holding and directing the flow of fluid, preventing leaks, maintaining specified pressure inside the hose and securely connecting the hose to other components in the hydraulic system such as cylinders, valves and pumps.

There are many different types of hydraulic hose fittings with a very wide range of thread types and forms. No matter the fitting, they should always be designed to be compatible with the specific hose, and with the fluid used.

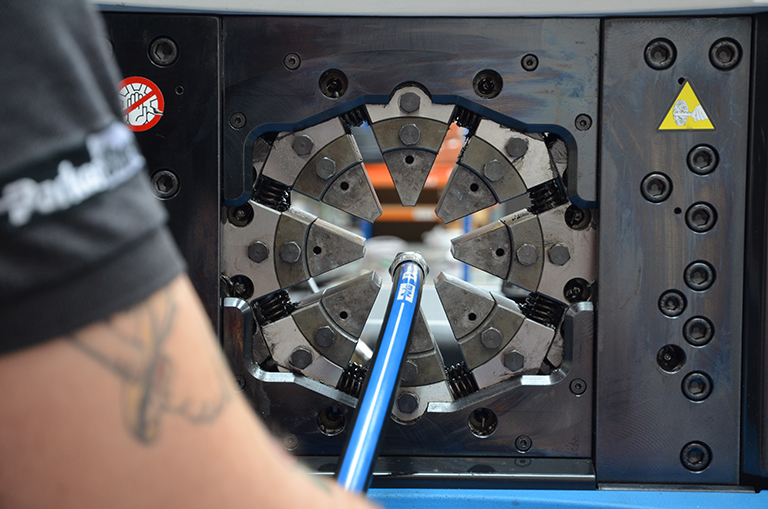

Hydraulic fittings are most commonly assembled using the crimp method. Fitting components comprise:

- A ferrule – This section of the fitting is attached over the outer layer of the hose.

- A hose insert – The insert pushes directly to the inner tube and extends out from the hose with the appropriate end thread, flange/fitting to attach to a component.

Hydraulic hoses and their fittings have to meet various specifications, and hoses are typically designed to comply with either EN standards or SAE standards – the latter being the most commonly used in the UK.

The different types of hydraulic hoses

There are many different types of hydraulic hose assemblies that are designed to perform to the requirements of different applications. Various factors play into which hose will be the most suitable for withstanding the environmental conditions of the system, but the main hydraulic hose categories are:

Braided hose

A high-pressure hose designed to operate in temperatures ranging from -40°C to 100°C, this hose is suitable for powering general industrial applications using petroleum or water-based fluids.

Multi-spiral hose

Ideal for use in heavy construction applications in industries such as mining, quarrying, oil industries and agriculture, multi-spiral hoses are highly flexible and used to transfer water-oil emulsions, and mineral & hydraulic oils.

Low-pressure hose

This type of hose is typically textile-braided, making it ideal for lighter operations with low operating pressure.

Stainless steel wire braided hose

A very heavy-duty hose typically designed with a single or double stainless steel wire braid, this type of hose is generally used in aggressive applications due to its durability and ability to withstand extreme pressures and temperatures.

Thermoplastic hydraulic hose

Typically found in hydraulic lift equipment, heavy construction and lubrication lines, these hoses feature two layers of thermoplastic material and a middle reinforcement layer of a synthetic fibre mesh. By design, thermoplastic hydraulic hoses are resistant to abrasion and can operate at very low temperatures.

Choosing a hydraulic hose

It goes without saying that hose assemblies are at the core of many hydraulic applications, and therefore choosing the right hose for the job is crucial to ensuring both optimal performance and safety.

If you’re in the market for a new or replacement hose, the best way to determine which hose your application requires is to use the S.T.A.M.P method:

- Size – Accurately sizing up the diameter needed for the hose to contain the correct amount of fluid will ensure that it is capable of performing at the required operating pressure.

- Temperature – It’s important to consider both the temperature of the fluid that will be contained in the hose and the temperature outside of the hose, to ensure the materials can withstand the conditions and have a greater lifespan.

- Application – Consider the environment in which the hose will be operating in, the type of equipment being used, and the specifications it needs to comply with.

- Media – The hose selected must be compatible with the fluid that will be housed in the inner tube, to ensure optimum performance and prevent abrasion or corrosion.

- Pressure – Accurately calculate the working pressure required, and select a hose with a maximum working pressure that either exceeds or matches the operating pressure of the system.

View this post on Instagram

Specialist hydraulic hose assemblies

No matter the application, improper hose selection can lead to catastrophic outcomes where both operations and health & safety are concerned. Seeking the help of a reputable manufacturer is highly recommended.

Derek Lane & Co have over 40 years of experience in the hydraulics industry, with unrivalled technical knowledge on hydraulic hose assemblies. Our highly skilled team of engineers can source and manufacture the right hydraulic hose assembly for your application.

By assessing pressure requirements, flow rate requirements, and application requirements, we can make recommendations on the perfect fit for the job. As part of our hydraulic hose assembly service, we are one of the only businesses in the UK to provide DefStan accredited specialist hydraulic hose assemblies suitable for defence, ships, MoD and aerospace.

Click here to find out more or get in touch with us to make an enquiry.