How to prevent hydraulic fluid contamination

Hydraulic fluid contamination is a common problem in many systems and can affect all types of hydraulic equipment. It’s one of the leading causes of hydraulic system failures.

Failing to identify or ignoring hydraulic fluid contamination can lead to catastrophic failures and cause severe damage to the system. Thankfully, for anyone operating hydraulic machinery, contamination can be avoided for the most part.

In this article, we’ll explore how contamination of hydraulic fluid can happen, and the precautions you can take to prevent this from affecting your system.

How does hydraulic fluid become contaminated?

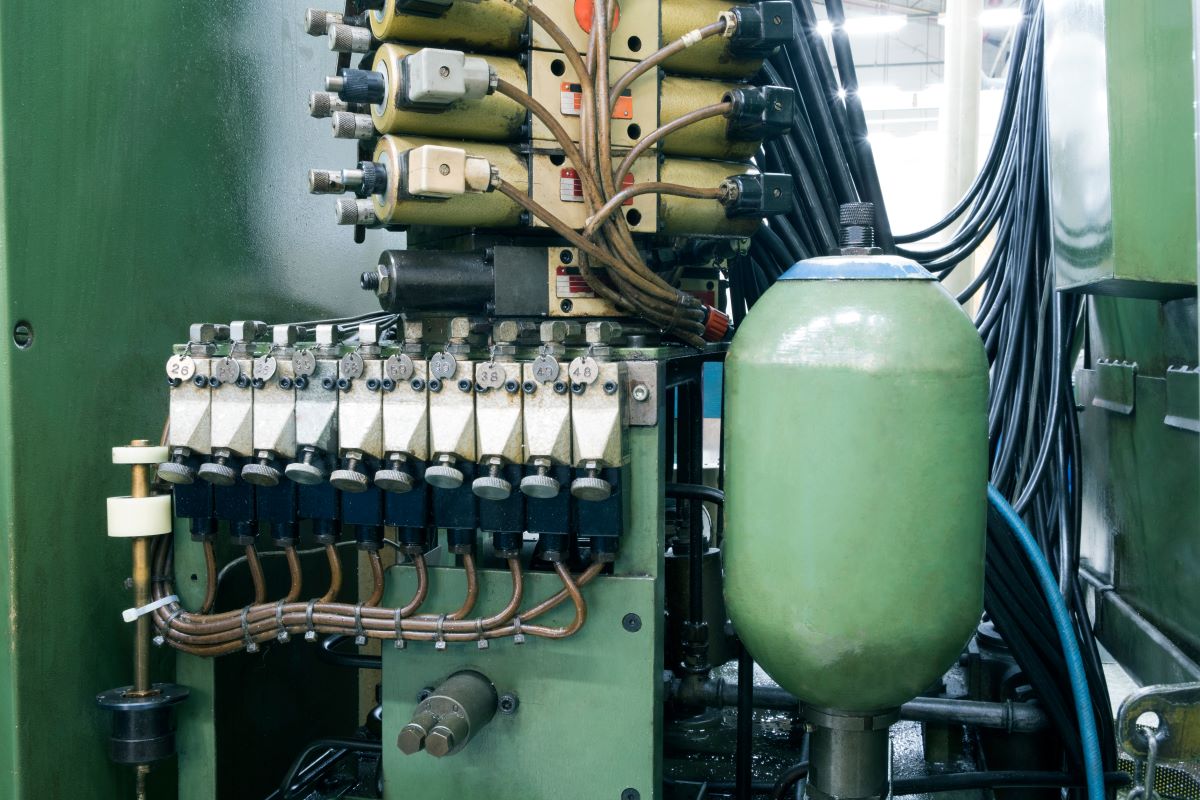

There are many ways in which contamination can occur in a hydraulic system. It can often be the case that external debris or air has entered the system, for example if it is left open, or it may have been generated by the system’s components.

Hydraulic fluid contamination may occur:

– When fluid is added to the system

– Through breather caps

– Through quick couplers on lines

– Due to wear and tear of components during operation

– Due to leaks around worn or damaged seals

– Whilst the system is open during maintenance and repairs

It’s often simpler to separate contamination into two main categories: Internal and external.

Internal contamination

Hydraulic fluid can become contaminated simply due to the nature of operating equipment, and this is classed as internal contamination.

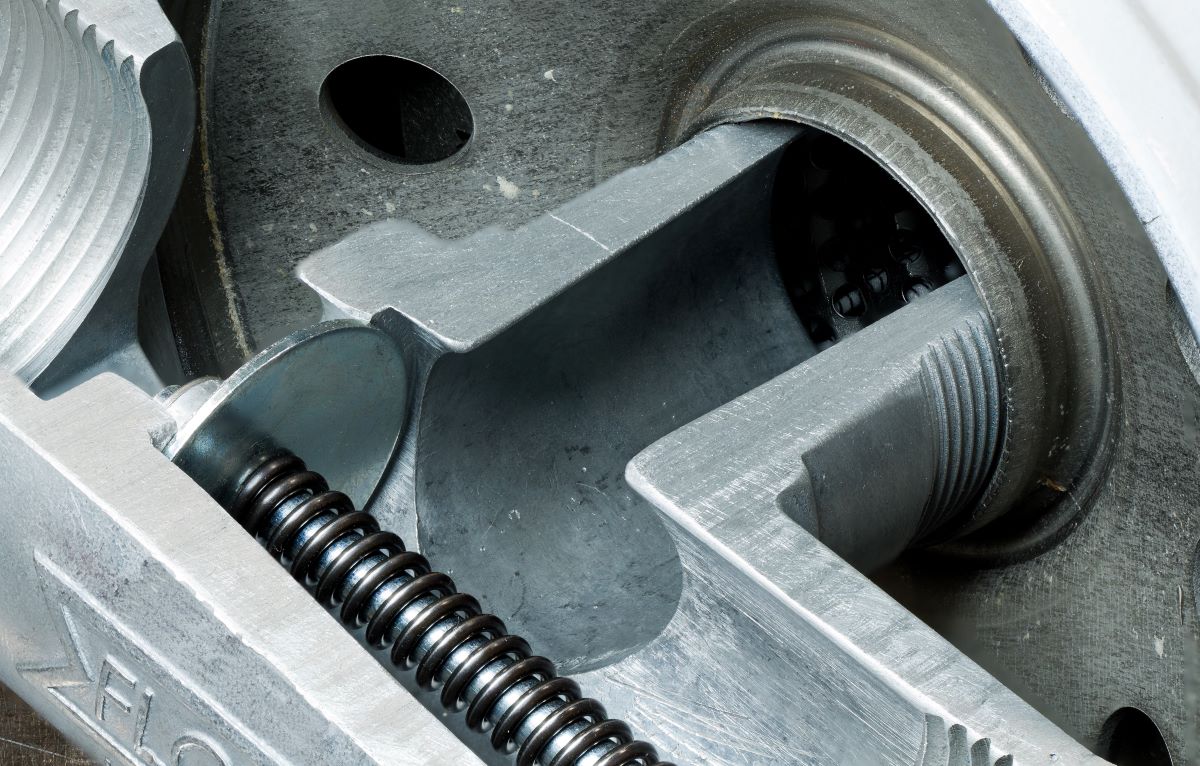

Hydraulic systems are made up of many different moving parts which will always generate some level of friction inside the circuit, leading to eventual wear and tear of the components. For example, rubber seals can begin to wear away over time which can result in particulate matter entering the system.

External contamination

External contamination refers to anything that travels into the system from the outside. This can be anything from air and water to debris and chemicals.

Even if you’re careful to keep your containers sealed, external contamination can also happen during the process of replenishing the system’s fluid. This can be due to the fluid not being completely clean or external contaminants entering the system whilst the reservoir is open.

How to prevent hydraulic fluid contamination

When it comes to preventing hydraulic fluid contamination, it’s important to be aware that all types of contamination can never truly be eliminated. Unfortunately, it’s part and parcel of operating a hydraulic system – there will always be a chance of contamination being introduced to the system.

However, if you’re neglecting your hydraulic system maintenance procedures and failing to take correct care of your components, you’re as good as inviting contamination into your machine.

Fortunately, there are a few simple and practical tips that can help you to prevent hydraulic fluid contamination.

Keep your machine clean

This may sound fairly obvious, but keeping your hydraulic machine as clean as possible can make all the difference when it comes to preventing contamination.

Regularly cleaning around the reservoir opening can help to prevent dirt, dust or any other debris from entering the system when replenishing the fluid. Simply brushing or washing away any debris before opening the reservoir can stop dirt from falling in.

Check and replace hydraulic filters

It’s a given that you should have some good hydraulic filters in place, but it’s important to ensure that they are being regularly checked and replaced when necessary.

Hydraulic filters are essential to keeping debris at bay, but they also can’t filter everything out. Especially when they’re clogged up. Ensure that your filters are high quality and can adequately collect any dirt before it enters the system, and regularly check them according to the manufacturer’s recommendations.

If you notice that your filters are clogged, replace them as soon as possible. A clogged up filter is just about as much use as no filter at all – so it’s wise to keep an eye on them.

Avoid reusing or mixing hydraulic fluid

Hydraulic fluid should never be reused, and different types of fluid should never be mixed together. When it’s time to replace your fluid, always ensure to use a clean supply and run it through a filter before adding it to the system, even if it’s brand new.

Don’t ignore leaks

Hydraulic leaks should always be treated with high priority, no matter how minor they may first appear. Leakage can cause catastrophic damage to a system, and can also provide a quick entrance for contaminants to enter.

If you notice a leak or crack in a hydraulic hose, or leak in a seal, replace it immediately.

Don’t leave the hydraulic system open

When considering the environmental conditions that hydraulic machinery usually operates in, there’s likely dust, sand or dirt surrounding the area. With that in mind, it’s important not to leave the hydraulic system open unnecessarily.

It’s common sense, but be sure to seal the openings as soon as possible after any fluid changes, repair or maintenance has taken place. The same goes for leaving components such as hydraulic pumps, valves and motors open, too.

If you’re looking for a hydraulic partner in the UK, get in touch with Derek Lane & Co. We supply reliable, high quality components alongside a range of specialist hydraulic engineered services to businesses across the UK.

We can assist in all of your hydraulic equipment repair needs and build bespoke solutions tailored to your specific requirements.