Selecting a hydraulic hose for your application

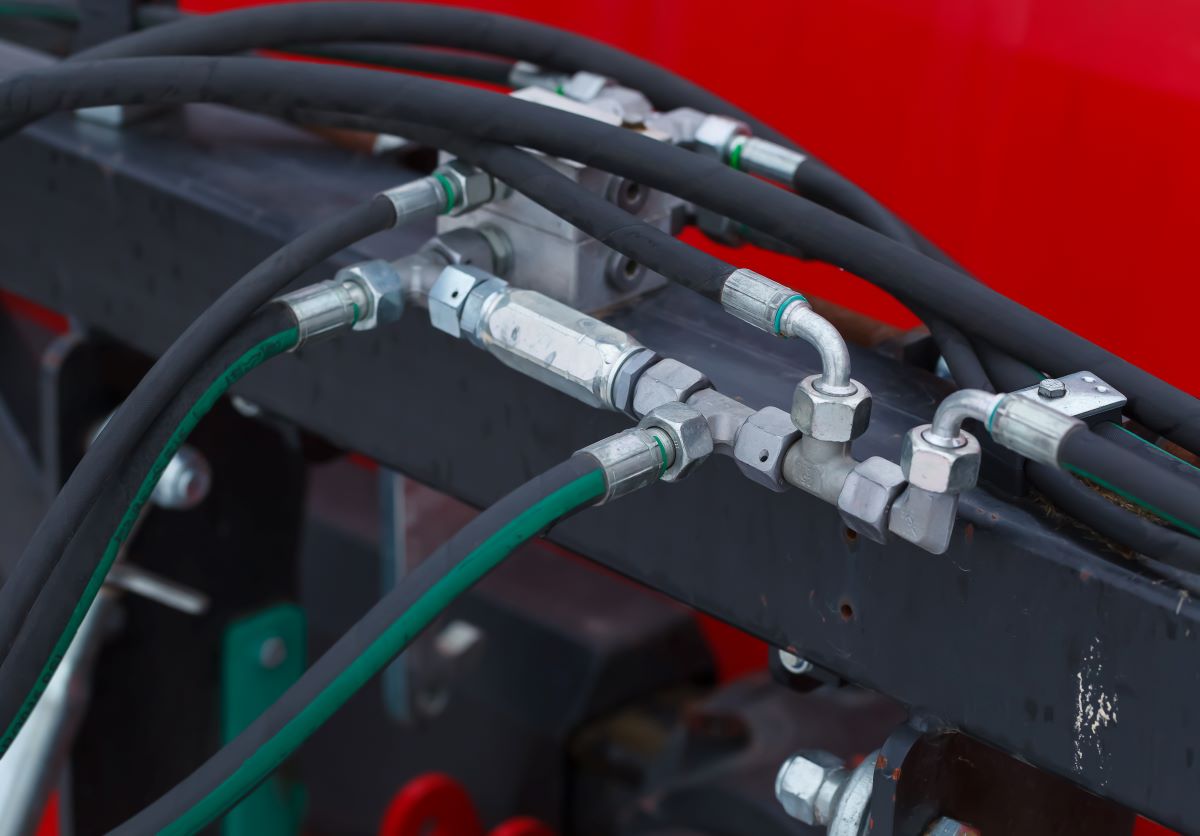

Hydraulic hoses are a crucial component of any hydraulic system. They play a vital role in keeping the system operational, by allowing the hydraulic fluid to flow from one component to another.

If you’re reading this article, you’re likely in the process of designing a new hydraulic system or working on a rebuild and aren’t too sure how to select the right hose for your application. We’re here to advise on how to size a hose correctly for any application, and all of the important things to consider.

First, let’s explore why it’s crucial to make sure the hydraulic hose you choose is fit for the job.

Dangers of improper hose selection

It goes without saying that safety is paramount when it comes to hydraulic systems, and particularly, the implementation of hose assemblies.

Where the best-case scenario of an unsuitable hose may be a mechanical failure due to a loss of hydraulic pressure, the worst-case scenario is a threat to life. Simply put, a hose that isn’t suitable for the application has the potential to kill.

It’s important to remember that hoses contain toxic pressurised hydraulic fluid which can lead to devastating consequences if released uncontrollably. This can result in fires and explosions, fluid burns or even fluid injections into the body.

An ill-fitting hose assembly is susceptible to breakage at any moment, which can lead to ‘hose whip’ where the hose breaks away at high speed and can dismember or kill anyone in its path. This may be a result of system pressure being higher than the working pressure rating of the hose, incorrect fittings, or anything similar.

Along with the risk of exposure to toxic fluids and physical harm, choosing an incompatible hose will naturally reduce its lifespan and require replacement, imposing unwanted system downtime.

Criteria for hydraulic hose selection

Now you know that accurate hydraulic hose selection is key to both safety and operations, let’s explore how to correctly select a hose assembly for your application.

The ‘STAMPED’ acronym is an industry-wide standard that should always be used when sizing up a compatible hose, no matter the scale of the application. This system defines the absolute critical list of things that need to be taken into consideration when designing a safe system.

The guideline for proper selection stands for:

Size | Temperature | Application | Material | Pressure | Ends | Delivery

Size

Measuring the size of a hose assembly applies to the inside diameter, overall length and outside diameter.

The inside diameter must be the correct size to minimise pressure loss and prevent excessive velocity and extremely high temperatures. Outside diameter measurements are crucial in applications where the hose is routed through a system and space is limited. Overall length is not the same as hose length and should include the added measurements of hose fittings.

It’s critical to be completely accurate with these measurements to ensure optimum efficiency and safety.

Temperature

Minimum, maximum and average temperatures that the hose will likely be exposed to should be specified. If the working temperature of the hose exceeds this range, it can shorten its lifespan and lead to catastrophic failures.

In environments where the hose may be exposed to extreme heat or cold this should be specified, as a protective hose jacket or heat shield may be recommended.

Application

Application refers to the environment in which the hose will operate and how it will be installed.

Important things to consider are:

– The configuration of the hose including orientation and routing

– Bend radius requirements including flexibility considerations

– Exposure to surge pressures above maximum working pressure

– Exposure to heat, flames, acids, sun, solvents

– Exposure to possible crushing, cutting, abrasion

– Conforming to standard specifications

Should any of these factors not be taken into account when selecting an assembly, potential exposure to these environmental impacts may reduce the lifespan and efficiency of the hose.

Material/Media

This refers to the media which is being transported through the hose, i.e. the hydraulic fluid. Specifying the exact chemical concentration which will be conveyed through the hose will ensure that the hose is suitable for exposure to the type of media.

A hose may require different liner materials depending on the media it will be in contact with, to ensure it can withstand the pressure and abrasiveness of the media.

Pressure

As straightforward as it sounds, this refers to how much pressure the hose will need to be able to withstand. Hose assemblies have a maximum working pressure which should be the same as, or greater than the overall system pressure.

A hose assembly should never be implemented into a system that has a higher operating pressure than the hose itself, as this can lead to hose failure and a shortened lifespan.

Ends/Couplings

The attachments and fittings that will be required should be specified, along with any gaskets or other accessories that may be needed.

Crucial information includes the type, style, thread, material, orientation and attachment method needed for a suitable hose connection.

Delivery

Finally, delivery is specific to your hose assembly requirements. This includes any specific testing and certification requirements, along with when and where the product should be shipped to and if any special handling or tracking is required.

Read more: Quick tips for hydraulic hose maintenance

Bespoke hydraulic hose assemblies

Identifying all of your STAMPED conditions is a crucial part of designing a hose assembly, whether you are purchasing the components and building it yourself or commissioning its manufacture.

To ensure the highest level of quality, efficiency and accuracy, we would always recommend seeking the help of a professional for your bespoke hydraulic hose assemblies.

Derek Lane & Co have over 40 years of experience in the hydraulics industry, with specialisms in hydraulic hose assemblies. We have the skills and expertise needed to recommend a suitable hose selection for your application, and can provide high-quality DefStan accredited, leak-free hose assemblies when the application requires.

Find out more about our specialist hydraulic hose assemblies, or get in touch with us to make an enquiry.