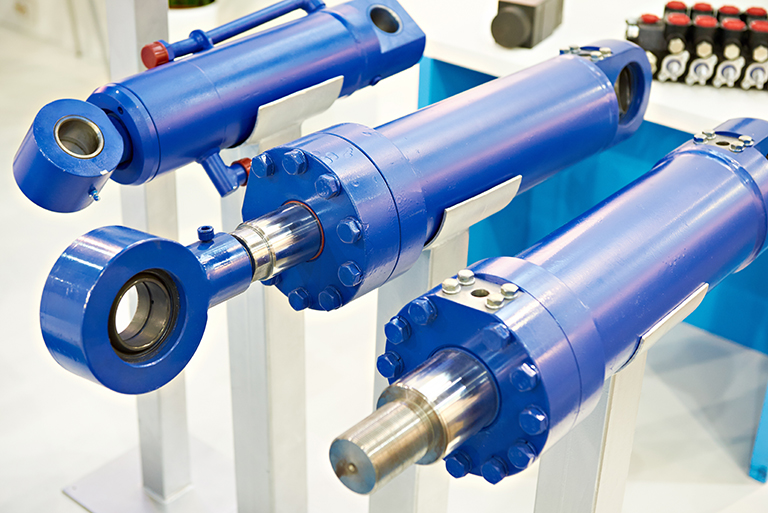

Hydraulic Cylinders / Actuators

Derek Lane & Co have over 40 years of experience in the field of hydraulic equipment, specialising in the design, build, installation, and repairs of components in any hydraulic system.

Our team of expert engineers have the skills and knowledge needed to advise on all hydraulic actuator requirements. We can recommend the most suitable hydraulic cylinder for your application, or offer bespoke actuator design and manufacture to meet your exacting specifications.

We also offer professional hydraulic cylinder repair services from our facility in Devon, including free cylinder assessment.

Custom Hydraulic Cylinder Builds

As a UK leading manufacturer in the hydraulic industry, you can be assured that Derek Lane & Co’s actuators are designed to industry standards, and manufactured for high-performance in the most demanding of applications.

We are committed to delivering the highest quality custom hydraulic cylinder solutions, with safety at the forefront. All of our off-the-shelf and bespoke actuators are manufactured with hard chrome steel piston rods.

We can accommodate custom mounting configurations with specialist seals available on request; from cylinder trunnion to flange mounted and rear clevis, amongst many others.

Derek Lane & Co’s hydraulic actuators are designed and manufactured on-site at our in-house state-of-the-art facility in Devon, UK. All equipment undergoes our rigorous testing procedure to ensure it meets or exceeds our expectations, before leaving the premises.

We can source and manufacture an extensive variety of hydraulic actuators, with specifications including:

- Tie-rod hydraulic actuators

- Bolted hydraulic actuators

- Electro-hydraulic linear actuators

- Double-acting hydraulic actuators

- Stainless steel options

- Seals specified to suit application

High Quality Hydraulic Actuator Repair

Our hydraulic engineers have experience with many varieties of actuator repair requirements, so any repair is possible.

The most common repairs are often simple seal replacements; hydraulic seals are the most susceptible part of an actuator and suffer from wear and tear, leading to leaks and inefficiencies in operation.

We manufacture and repair hydraulic rams to suit the individual requirements of our clients. Here is a selection of the range of products we provide repairs for:

• Single acting

• Double acting

• Subsea and offshore

• Telescopic

• Displacement

• Rod feed

• High pressure

• Trunion mounted

• Spring return

No matter where you are located in the UK, we are here to help. All repairs are carried out by our teams to stringent processes and we guarantee 100% customer satisfaction. You will receive your repaired hydraulic actuator fully tested and ready for installation.

Types of hydraulic cylinders

Bolted

Commonly referred to as mill cylinders, these cylinders are generally found in heavy-duty arduous industrial and marine applications. Manufactured to the most exacting standards, bolted cylinders conform to ISO 6022 mounting requirements, with dimensions available from 40mm bore to 320mm bore. This robust type of cylinder is recommended for applications that are likely to experience internal pressure spikes and high shock loads. Options include built-on manifold valve packages and internal linear transducers.

Tie Rod

Commonly used in machine tools and process machine applications, tie rod hydraulic cylinders are built to conform to ISO 6020/2. Available with bore diameters ranging from 25mm to 200mm, tie rod cylinders can be supplied with or without end-of-stroke cushioning, depending on the requirements of the application.

Welded

This type of hydraulic cylinder is designed whereby the barrel is welded directly to the end caps, and the ports welded to the barrel. These are medium duty cylinders, available with bore diameters ranging from 25mm bore to 250mm bore. There are a range of welded hydraulic cylinders available with a range of custom mounting options to suit any application.

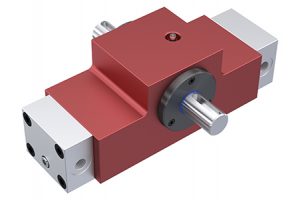

Rotary

Hydraulic rotary actuators work to generate exceptionally high torque in small spaces with the use of hydraulic pressure. Built to withstand high operating pressures, these actuators can be supplied as single or double rack versions, fail-safe or double-acting. We have a choice of sizes and angles of rotation available to deliver the exact combination of torque and pressure output required.

Not sure what type of hydraulic actuator you need for your application? Derek Lane & Co. can help. Simply get in touch with us and our team of technical engineers will recommend or design the most suitable cylinder for you.

FAQ

Here you will find answers to the most commonly asked questions about hydraulic cylinders/actuators.

Hydraulic actuators are mechanical devices in a hydraulic system that generate physical motion and enable movement in an application – by converting energy into mechanical force.

Actuators can be used for the movement and control of many parts within a mechanical system, such as the opening of a hydraulic valve.

There is no difference between hydraulic actuators, cylinders or rams. They are all the same pieces of equipment, but their names have evolved over time.

They are most commonly referred to as hydraulic cylinders nowadays but were traditionally called actuators – due to their primary goal being to move objects.

As the demands of systems grew and industries required more power to be generated, they were then also given the title of rams. The name cylinders came about due to the design of the equipment – mechanical equipment housed in a hollow box/cylinder.

Actuators take three different forms: hydraulic, pneumatic and electrical.

Hydraulic actuators are the most powerful of the three and are perfectly suited to exerting large forces in industrial applications.

Electric actuators are ideal for applications that require great precision and accuracy during movement.

Pneumatic cylinders work best where speed and accuracy are of the utmost importance, and power isn’t high up the priority list.